Fix Code P0107 Chevy: Easy Solutions for a Faulty MAP Sensor

Brief explanation of the significance of the MAP sensor in a Chevy vehicle. The MAP sensor, or Manifold Absolute Pressure sensor, plays a crucial role in regulating the engine's performance. It measures the pressure inside the intake manifold and sends this data to the engine control unit (ECU). This information is used by the ECU to adjust the air-fuel mixture and ignition timing, ensuring optimal engine performance and fuel efficiency.

However, a faulty MAP sensor can lead to various issues, one of which is the P0107 error code. The P0107 code indicates a problem with the MAP sensor circuit, specifically a low voltage output. This code can trigger the check engine light and cause noticeable symptoms such as rough idling, poor acceleration, and decreased fuel efficiency.

The purpose of this article is to provide easy solutions for fixing the P0107 code in a Chevy. Whether you are an experienced mechanic or a DIY enthusiast, you will find step-by-step instructions and helpful tips to diagnose and repair the issue.

Understanding the MAP Sensor

A MAP sensor is a vital component of the engine management system in a Chevy vehicle. Its main function is to measure the pressure inside the intake manifold, which reflects the load on the engine. This information helps the ECU determine how much fuel to inject and when to ignite the air-fuel mixture.

The MAP sensor works by using a diaphragm that responds to changes in manifold pressure. This diaphragm is connected to a variable resistor or a semiconductor inside the sensor. As the pressure changes, it causes the diaphragm to move, altering the resistance or voltage output of the sensor. This change in voltage is then interpreted by the ECU.

The MAP sensor's role is critical in maintaining proper engine performance. Without accurate manifold pressure readings, the engine may run too rich or too lean, resulting in decreased power, decreased fuel efficiency, and potential damage to engine components.

Causes of P0107 Code

- Faulty MAP sensor

- Wiring issues, such as short circuits or open circuits

- Vacuum leaks in the intake manifold or vacuum hoses

When any of these issues occur, they can cause the MAP sensor to provide incorrect readings or no readings at all. This triggers the P0107 code and negatively affects engine performance.

It is important to identify the specific cause of the P0107 code in order to implement the appropriate fix. In the following sections, we will discuss symptoms of a faulty MAP sensor, diagnostic procedures, and recommended solutions.

Symptoms of a Faulty MAP Sensor

A faulty MAP sensor can manifest through various symptoms. While the presence of the P0107 code is a clear indication of a problem, it is important to also be aware of the common symptoms associated with a faulty MAP sensor. These symptoms may include:

- Rough idling: The engine may have an irregular or unstable idle, often accompanied by vibrations

- Poor acceleration: The vehicle may struggle to accelerate smoothly, lacking power and responsiveness

- Decreased fuel efficiency: The engine may consume more fuel than usual, resulting in decreased mileage

In some cases, there may be additional symptoms that indicate a faulty MAP sensor. These symptoms may include:

- Black smoke from the exhaust: The engine may produce excessive black smoke, indicating a rich air-fuel mixture

- Engine misfires: The engine may misfire or hesitate during acceleration or idle

It is important to note that these symptoms can also be caused by other issues. However, if you are experiencing one or more of these symptoms in conjunction with the P0107 code, it is highly likely that the MAP sensor is the culprit.

Diagnosing the P0107 Code

Diagnosing the P0107 code begins with connecting an OBD-II scanner to the vehicle's diagnostic port. The scanner will retrieve the error codes stored in the ECU and provide valuable information for the diagnostic process. In addition to the P0107 code, it is important to check for any other related error codes, as multiple codes can provide a more complete picture of the issue.

Once you have retrieved the error codes, it is recommended to perform a visual inspection of the MAP sensor and its wiring. Look for any signs of damage, loose connections, or corrosion. These can be indications of a faulty MAP sensor or wiring issues.

Proper diagnostic procedures will help pinpoint the exact cause of the P0107 code, ensuring that you implement the appropriate fix. In the following sections, we will discuss the testing methods for the MAP sensor, checking the MAP sensor wiring, and inspecting for vacuum leaks.

Testing the MAP Sensor

To determine if the MAP sensor is functioning correctly, it is essential to perform specific tests. The two common methods for testing the MAP sensor include using a multimeter to measure the voltage output and using a vacuum pump to create pressure.

Testing Voltage Output: Start by disconnecting the electrical connector from the MAP sensor. Set your multimeter to the appropriate voltage setting and connect the positive lead to the signal wire (usually a colored wire). Connect the negative lead to a ground. With the engine off, turn the ignition key to the ON position, but do not start the engine. You should measure a reference voltage of around 5 volts. If the voltage is significantly different, it may indicate a faulty MAP sensor.

Testing Pressure Output: If the voltage output test indicates a potential issue with the MAP sensor, you can also perform a pressure output test. This requires the use of a vacuum pump. Disconnect the vacuum hose from the MAP sensor and connect the vacuum pump. Apply pressure to the sensor gradually while monitoring the voltage output. The voltage should increase as the pressure increases. If there is no change in voltage or if the voltage fluctuates irregularly, it may indicate a faulty MAP sensor.

Interpret the test results based on the specifications provided by the vehicle manufacturer. If the test results indicate a faulty MAP sensor, it will need to be replaced.

Checking MAP Sensor Wiring

In addition to testing the MAP sensor, it is crucial to check the wiring for any signs of damage or loose connections. Start by visually inspecting the wiring harness connected to the MAP sensor. Look for any frayed wires, exposed connectors, or signs of corrosion.

If any damage is found, repairs should be made. This may involve repairing or replacing damaged sections of the wiring, ensuring proper insulation and protection. If no physical damage is apparent, it is recommended to check for proper grounding of the MAP sensor.

Proper grounding is essential for accurate MAP sensor readings. Check for any loose or corroded grounding points and clean or tighten them as necessary. A bad ground connection can cause erratic readings or prevent the MAP sensor from functioning correctly.

Inspecting for Vacuum Leaks

Vacuum leaks can disrupt the intake manifold's pressure, resulting in incorrect MAP sensor readings and triggering the P0107 code. It is important to inspect for vacuum leaks using appropriate methods.

Smoke Test: A smoke test involves introducing smoke into the intake system and looking for any signs of smoke escaping from potential leak points. This method is often used by professionals and requires specialized equipment. If you don't have access to a smoke machine, it is best to proceed with other inspection methods.

Listening for Hissing Sounds: Start the engine and listen for any hissing sounds around the intake manifold or vacuum hoses. A leaking vacuum hose or gasket may produce a distinct hissing noise. If you hear any such noise, inspect the area for signs of a leak, such as visible cracks or loose connections.

Visual Inspection: Perform a visual inspection of the intake manifold gaskets, vacuum hoses, and any other components in the intake system. Look for any signs of wear, cracks, or visible damage. Pay close attention to the connection points and ensure they are secure.

If any vacuum leaks are found during the inspection, they should be addressed promptly. Depending on the severity of the leak, it may be necessary to replace gaskets or hoses. Ensure that all connections are secure and airtight.

Fixing the P0107 Code

After diagnosing the cause of the P0107 code, it is time to implement the appropriate fix. The specific fix depends on the cause identified during the diagnostic process: a faulty MAP sensor, wiring issues, or vacuum leaks.

Note: While the following steps provide general guidance, it is always recommended to consult your vehicle's service manual or seek professional assistance for more specific instructions.

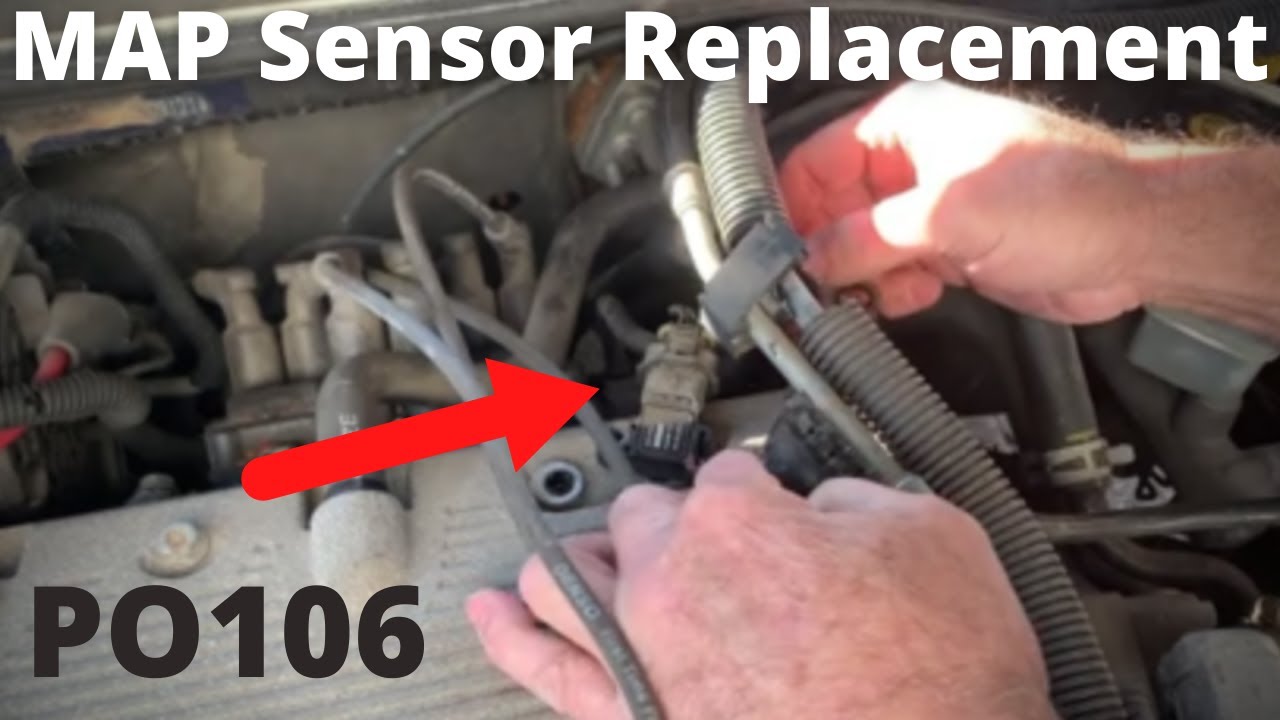

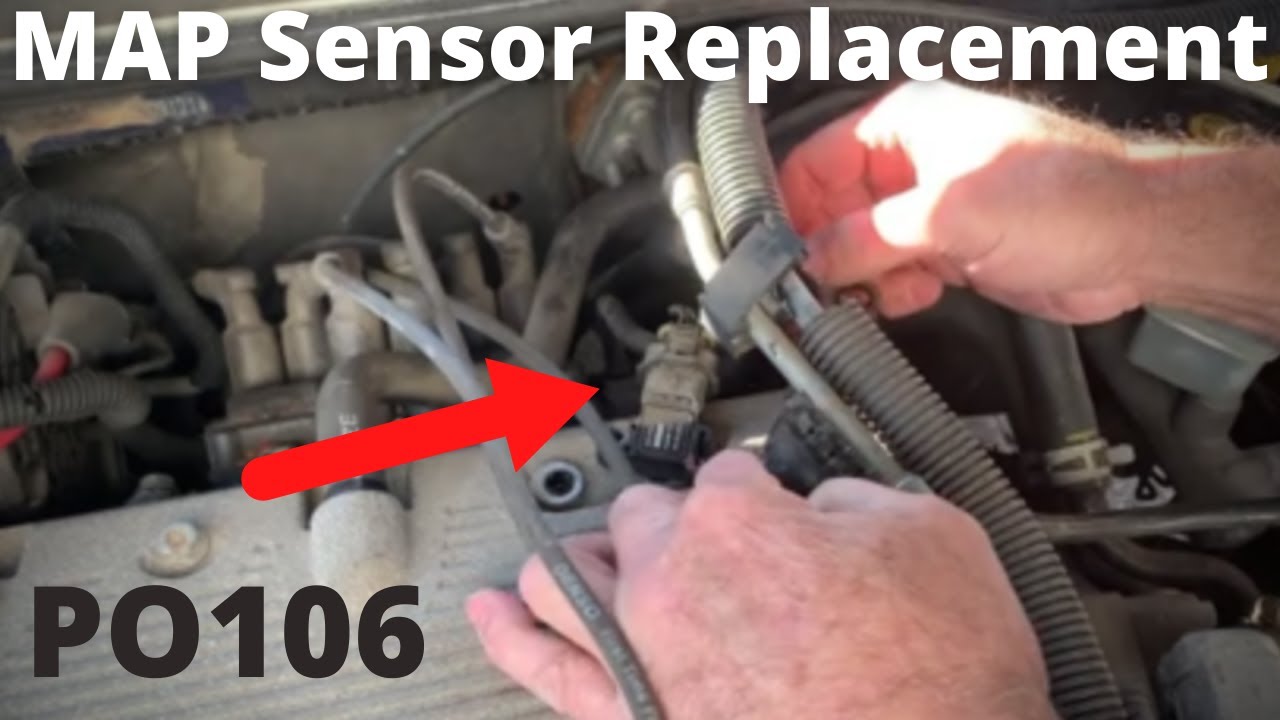

Replacing a Faulty MAP Sensor

If the MAP sensor has been determined to be faulty after testing, it will need to be replaced. Follow these steps to replace the MAP sensor:

- Disconnect the negative terminal of the vehicle's battery to ensure safety.

- Locate the faulty MAP sensor, typically found on or near the intake manifold. Refer to your vehicle's service manual for the exact location.

- Disconnect the electrical connector from the MAP sensor, taking care not to damage the connector or wiring.

- Remove any mounting screws or bolts holding the MAP sensor in place and carefully remove the sensor.

- Install the new MAP sensor, ensuring it is securely mounted and aligned correctly.

- Reconnect the electrical connector to the new MAP sensor.

- Reconnect the negative terminal of the vehicle's battery.

Important: When replacing a MAP sensor, it is essential to use an OEM or high-quality aftermarket part. Inferior quality sensors may fail prematurely or provide inaccurate readings, leading to further issues down the line.

Repairing Damaged Wiring

If the diagnostic process reveals damaged wiring as the cause of the P0107 code, follow these steps to repair the wiring:

- Disconnect the negative terminal of the vehicle's battery to ensure safety.

- Identify the damaged section of the MAP sensor wiring, using the visual inspection conducted earlier.

- Cut out the damaged section of the wiring, leaving sufficient length for splicing.

- Strip the insulation off the ends of the wires on either side of the cut, ensuring they are clean and free of any residue.

- Connect the corresponding wires on either side of the cut using crimp connectors or soldering them together.

- Wrap the repaired section with electrical tape or use heat shrink tubing to insulate and protect the repaired wiring.

- Reconnect the negative terminal of the vehicle's battery.

Ensure that the repaired wiring is properly insulated and protected from elements that may cause further damage, such as heat or moisture.

Fixing Vacuum Leaks

If vacuum leaks are identified as the cause of the P0107 code, follow these steps to fix the leaks:

- Disconnect the negative terminal of the vehicle's battery to ensure safety.

- Locate the source of the vacuum leak by visually inspecting the intake manifold gaskets, vacuum hoses, and other components in the intake system.

- If a gasket is found to be faulty, remove the intake manifold, replace the gasket, and reinstall the manifold. Ensure that all connections are secure and tightened to the manufacturer's specifications.

- If a vacuum hose is found to be faulty, disconnect the hose from both ends and replace it. Make sure the new hose is the correct size and length for proper installation.

- If a loose connection is found, tighten the connection securely.

- Reconnect the negative terminal of the vehicle's battery.

Once the vacuum leaks are fixed, perform a final inspection to ensure that all potential leak points have been addressed. This will help prevent any recurring issues related to vacuum leaks.

Preventing Future MAP Sensor Issues

Preventing future MAP sensor issues is crucial for maintaining a healthy engine and avoiding costly repairs. Here are some tips and recommendations:

- Regular inspections: Regularly inspect the MAP sensor and its connections for signs of damage, corrosion, or loose connections. Catching potential issues early can prevent them from escalating.

- Cleaning: Over time, the MAP sensor may accumulate dirt and debris, affecting its performance. Cleaning the sensor periodically can help prevent issues related to dirt buildup. Use a specialized cleaner designed for MAP sensors and follow the instructions provided by the manufacturer.

- Avoiding harsh driving conditions: Aggressive driving, frequent high RPMs, or sustained heavy loads can put additional strain on the engine and the MAP sensor. Avoiding such driving conditions can help prolong the lifespan of the sensor.

- Addressing engine issues promptly: If you notice any engine-related issues, such as unusual noises, hesitation, or loss of power, address them promptly. Ignoring these issues can lead to further damage to the engine and potentially the MAP sensor.

By following these preventive measures, you can reduce the likelihood of encountering MAP sensor issues and the associated P0107 code.

In conclusion, a functioning MAP sensor is crucial for optimal engine performance in a Chevy vehicle. If you encounter the P0107 code, it is important to address the issue promptly. This article has provided detailed information on the significance of the MAP sensor, symptoms of a faulty sensor, diagnostic procedures, and recommended solutions.

By following the recommended diagnostic steps and implementing the appropriate fix, you can resolve the P0107 code and restore proper engine performance. Whether you choose to replace a faulty MAP sensor, repair damaged wiring, or fix vacuum leaks, always prioritize using high-quality parts and following the manufacturer's guidelines.

Remember, if you are unsure about any step of the diagnostic or repair process, it is recommended to consult a professional mechanic or refer to your vehicle's service manual. With the right tools, knowledge, and confidence, you can successfully fix the P0107 code in your Chevy vehicle.

P0107 chevrolet

The P0107 code in Chevrolet vehicles refers to a faulty MAP sensor. The MAP sensor, or Manifold Absolute Pressure sensor, is responsible for measuring the intake manifold pressure and sending this information to the engine control module (ECM). The ECM uses this data to calculate the correct air-fuel mixture for optimal engine performance.

When the P0107 code is triggered, it means that the ECM has detected a low voltage signal from the MAP sensor. This could be caused by a variety of issues, such as a faulty sensor, a loose or damaged electrical connection, or a vacuum leak in the intake manifold.

One of the most common symptoms of a P0107 code is poor engine performance. The vehicle may experience hesitation, rough idle, or stalling. Other symptoms may include poor fuel efficiency and an illuminated check engine light. It's important to address this issue promptly to avoid further damage to the engine.

To fix the P0107 code in a Chevrolet vehicle, there are a few easy solutions you can try. First, you should inspect the electrical connections to ensure they are secure and free from corrosion. If any damage or corrosion is found, the connections should be cleaned or replaced.

If the electrical connections are in good condition, the next step is to test the MAP sensor using a multimeter. This will help determine if the sensor is functioning properly or if it needs to be replaced. If the MAP sensor is found to be faulty, it should be replaced with a new one to resolve the P0107 code.

If you want to know other articles similar to Fix Code P0107 Chevy: Easy Solutions for a Faulty MAP Sensor you can visit the category Automotive Mechanics.