Complete Guide to Kubota 3 Cylinder Diesel Injection Pump Manual

- Understanding the Tractor Kubota 3 Cylinder Diesel Injection Pump Manual

- A Step-by-Step Guide to Troubleshooting Tractor Kubota 3 Cylinder Diesel Injection Pump

- How to Properly Maintain Your Tractor Kubota 3 Cylinder Diesel Injection Pump

- Common Issues and Solutions for Tractor Kubota 3 Cylinder Diesel Injection Pump

- The Importance of Regular Servicing for Tractor Kubota 3 Cylinder Diesel Injection Pump

Understanding the Tractor Kubota 3 Cylinder Diesel Injection Pump Manual

When it comes to understanding the tractor Kubota 3 cylinder diesel injection pump manual, it's essential to familiarize yourself with the key components and functions. The manual provides detailed insights into the operation, maintenance, and troubleshooting of the injection pump, ensuring the optimal performance of your Kubota tractor. By referring to the manual, tractor operators gain valuable knowledge about the injection pump's configuration, including the fuel delivery system and associated components.

One of the primary focuses of the manual is to guide users through the proper maintenance procedures for the diesel injection pump. This includes instructions for regular checks, cleaning, and potential adjustments to ensure the pump operates efficiently. Furthermore, it offers troubleshooting guidance to address common issues that may arise, enabling operators to diagnose and resolve problems effectively.

The Kubota 3 cylinder diesel injection pump manual is an indispensable resource for ensuring the reliability and longevity of your tractor's fuel system. By understanding the information provided in the manual, operators can confidently manage the injection pump and optimize the performance of their Kubota tractor. It's a valuable tool that equips users with the knowledge and skills necessary to maintain the integrity of the fuel delivery system.

A Step-by-Step Guide to Troubleshooting Tractor Kubota 3 Cylinder Diesel Injection Pump

When troubleshooting the Kubota 3 cylinder diesel injection pump in your tractor, it's essential to follow a step-by-step approach to identify and address any issues. Begin by visually inspecting the injection pump for any signs of leaks, damage, or excessive wear. Next, check the fuel filter and fuel lines for any blockages or clogs that may be affecting the pump's performance. Once the external components have been inspected, it's important to test the pump's internal components for proper functionality.

After visually inspecting the injection pump and ensuring the integrity of the fuel system, it's time to move on to testing the pump's performance. Use a fuel pressure gauge to check the pressure output of the injection pump during operation. If the pressure is below the manufacturer's specifications, it may indicate a problem with the pump's internal components or fuel delivery system. Additionally, testing the injection pump's timing and fuel delivery rate can help identify any potential issues that may be affecting its performance.

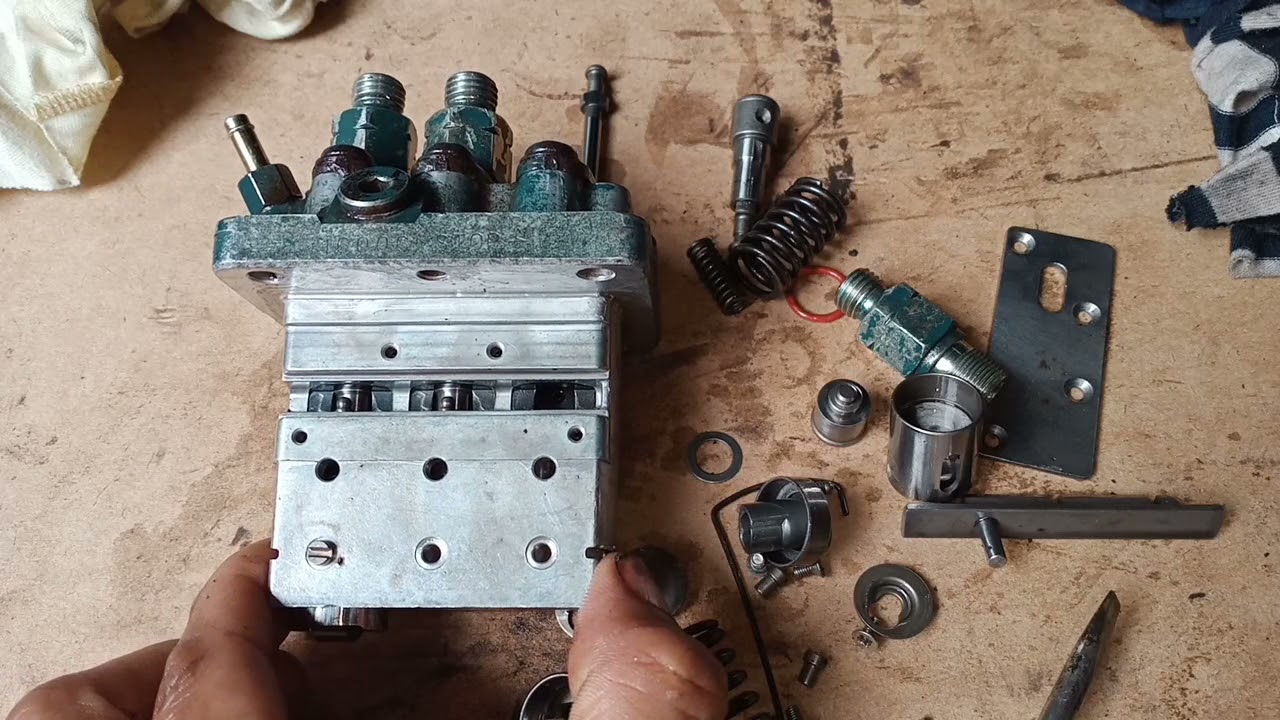

In some cases, troubleshooting the Kubota 3 cylinder diesel injection pump may require disassembly and inspection of its internal components. This can involve checking the condition of the pump's pistons, valves, seals, and any other moving parts. It's important to pay close attention to any signs of wear, damage, or contamination that may be impacting the pump's performance. By following a systematic approach to troubleshooting the injection pump, it's possible to identify and address any issues that may be affecting your tractor's performance.

How to Properly Maintain Your Tractor Kubota 3 Cylinder Diesel Injection Pump

Proper maintenance of your tractor's Kubota 3-cylinder diesel injection pump is crucial to ensure optimal performance and longevity. Regular maintenance tasks include inspecting for leaks, checking fuel quality, and cleaning or replacing the fuel filters. It's important to adhere to the manufacturer's guidelines for maintenance intervals and procedures to prevent costly repairs and downtime.

Inspecting the injection pump for any signs of leaks, such as diesel fuel or oil, is essential to prevent potential damage to the system. Addressing leaks promptly can help prevent major issues that may lead to expensive repairs. Additionally, regular checks of the fuel quality, including water and sediment content, can help maintain the efficiency of the injection pump and prevent clogs or damage.

Cleaning or replacing the fuel filters at recommended intervals is crucial for proper maintenance of the injection pump. The filters play a critical role in preventing contaminants from reaching the fuel injection system, which can cause damage and decrease performance. Regularly inspecting and maintaining the filters can help ensure smooth operation and prevent premature wear of the injection pump components.

Proper maintenance of the tractor's Kubota 3-cylinder diesel injection pump is essential for ensuring reliable operation and minimizing the risk of unexpected breakdowns. By adhering to the recommended maintenance procedures and intervals, tractor owners can protect their investment and maintain the performance and efficiency of their equipment.

Common Issues and Solutions for Tractor Kubota 3 Cylinder Diesel Injection Pump

When it comes to the operation of a Kubota 3 cylinder diesel injection pump in a tractor, there are several common issues that can arise. One of the most frequent problems is air entering the fuel system, which can lead to improper fuel delivery and engine stalling. This issue can often be resolved by checking for leaks in the fuel lines and ensuring that all connections are tightened securely.

Another common issue is the buildup of sediment and debris in the fuel filter, leading to restricted fuel flow and potential engine damage. Regularly replacing the fuel filter and cleaning the fuel system can help prevent this issue and ensure smooth operation of the injection pump.

Additionally, wear and tear on the injection pump components over time can lead to decreased performance and fuel efficiency. Proper maintenance and timely replacement of worn parts can address this issue and extend the lifespan of the injection pump.

The Importance of Regular Servicing for Tractor Kubota 3 Cylinder Diesel Injection Pump

Regular servicing of the Tractor Kubota 3 Cylinder Diesel Injection Pump is crucial for maintaining optimal performance and extending the lifespan of the equipment. The injection pump is a critical component of the tractor's engine, responsible for delivering the precise amount of fuel for combustion. Over time, the pump can accumulate dirt, debris, and wear, leading to decreased efficiency and potential malfunctions. By adhering to a routine servicing schedule, tractor owners can ensure that the injection pump operates at peak performance, minimizing the risk of costly repairs and downtime.

During regular servicing, experienced technicians can thoroughly inspect the Tractor Kubota 3 Cylinder Diesel Injection Pump for any signs of wear, damage, or contamination. This proactive approach allows for the early detection of potential issues, preventing them from escalating into major problems that could disrupt agricultural operations. Additionally, servicing may involve cleaning or replacing the pump's components, including filters and seals, to maintain fuel delivery accuracy and safeguard the engine from harmful particles. Ultimately, prioritizing regular servicing of the injection pump contributes to the overall reliability and efficiency of the tractor, promoting uninterrupted productivity on the farm.

Neglecting the regular servicing of the Tractor Kubota 3 Cylinder Diesel Injection Pump can lead to diminished performance, increased fuel consumption, and decreased power output. Without proper maintenance, the injection pump may become vulnerable to corrosion, internal damage, or clogging, jeopardizing the tractor's operational integrity. By emphasizing the significance of consistent servicing, tractor owners can protect their investment, preserve engine efficiency, and prevent unexpected breakdowns, safeguarding the continuity of agricultural activities. Regular maintenance is the key to ensuring the reliable and enduring performance of the Tractor Kubota 3 Cylinder Diesel Injection Pump, contributing to the overall productivity and profitability of farming operations.

Key Points:

- Regular servicing of the Tractor Kubota 3 Cylinder Diesel Injection Pump is essential for sustaining peak performance and longevity.

- Scheduled maintenance allows for comprehensive inspection, cleaning, and replacement of components to prevent potential issues.

- Neglecting servicing can lead to reduced efficiency, increased fuel consumption, and compromised engine reliability.

If you want to know other articles similar to Complete Guide to Kubota 3 Cylinder Diesel Injection Pump Manual you can visit the category Automotive Mechanics.