Expert Guide to Kubota Tractor Hydraulics Troubleshooting

- The Common Kubota Tractor Hydraulics Issues You May Encounter

- Understanding Hydraulic System Components in Kubota Tractors

- Step-by-Step Guide for Troubleshooting Kubota Tractor Hydraulics

- Tips for Maintaining Kubota Tractor Hydraulics

- Consulting a Professional for Complex Kubota Tractor Hydraulics Problems

The Common Kubota Tractor Hydraulics Issues You May Encounter

When operating a Kubota tractor, you may encounter various hydraulic issues that can impact the performance and functionality of the equipment. Understanding these common problems is essential for troubleshooting and maintaining the hydraulic system of your Kubota tractor.

One common issue that Kubota tractor owners may encounter is hydraulic fluid leaks. These leaks can occur at the hoses, fittings, or seals of the hydraulic system, leading to a loss of fluid and reduced hydraulic pressure. Identifying and repairing these leaks promptly is crucial to prevent further damage and ensure the proper functioning of the hydraulic system.

Another potential problem is hydraulic cylinder malfunctions, which can result in issues such as slow or erratic movement of attached implements. This can be caused by internal damage, worn seals, or contamination within the hydraulic system. Regular inspection and maintenance of the hydraulic cylinders are essential to prevent such issues.

Moreover, a common hydraulic issue is inadequate hydraulic power, which can manifest as slow or weak operation of the tractor's hydraulics. This can be caused by factors such as low hydraulic fluid levels, a worn hydraulic pump, or clogged filters. Regularly checking and maintaining the hydraulic fluid level and components can help prevent this issue from affecting the tractor's performance.

In summary, being aware of the common hydraulic issues that can arise with Kubota tractors is vital for ensuring smooth operation and preventing potential equipment downtime. Regular inspection, maintenance, and prompt resolution of hydraulic issues are essential to keep the tractor's hydraulic system functioning optimally.

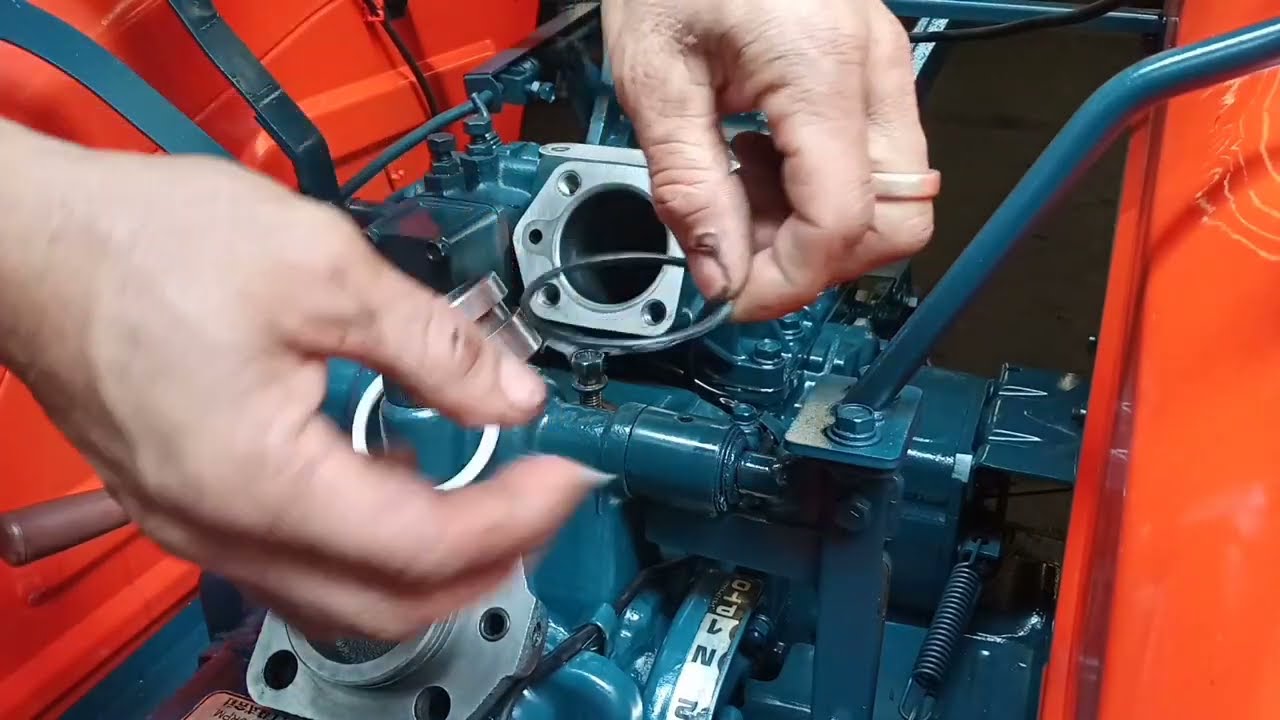

Understanding Hydraulic System Components in Kubota Tractors

The hydraulic system is a crucial component in Kubota tractors, responsible for powering various attachments and implements. Understanding the hydraulic system components is essential for ensuring the smooth operation and maintenance of these tractors. The main components of the hydraulic system in Kubota tractors include the hydraulic pump, hydraulic fluid, control valves, and hydraulic cylinders. The hydraulic pump is the heart of the system, responsible for generating the hydraulic pressure required to operate the various functions of the tractor. It is important to regularly check and maintain the hydraulic pump to ensure optimal performance.

In addition to the hydraulic pump, the hydraulic fluid plays a critical role in the overall functionality of the system. It is essential to use the recommended hydraulic fluid and keep it at the proper level to prevent system malfunctions and potential damage. The control valves in the hydraulic system regulate the flow and pressure of the hydraulic fluid, allowing for precise control of the tractor's hydraulic functions. Proper maintenance and periodic inspection of the control valves are necessary to prevent leaks and ensure smooth operation.

Finally, the hydraulic cylinders are the muscle of the hydraulic system, converting the hydraulic pressure into mechanical force to operate the various attachments and implements. It is important to inspect the hydraulic cylinders for any signs of wear or damage and replace them as needed to maintain the efficiency and safety of the tractor. Understanding these hydraulic system components is vital for the proper functioning and longevity of Kubota tractors. Regular maintenance and attention to these components can help prevent costly repairs and downtime.

Step-by-Step Guide for Troubleshooting Kubota Tractor Hydraulics

When it comes to troubleshooting Kubota tractor hydraulics, it’s essential to follow a systematic approach to identify and resolve any issues effectively. Understanding the hydraulic system's components and how they work together is crucial in this process. By following a step-by-step guide, you can pinpoint common problems such as leaks, low fluid levels, or malfunctioning valves.

Start by examining the hydraulic fluid level and condition. Low fluid levels can cause poor system performance, while contaminated fluid can lead to component damage. Inspect the hydraulic hoses and fittings for any signs of leaks or damage, as these can significantly impact the system's operation. Additionally, checking the condition of filters and screens is vital as they can become clogged with debris, affecting overall performance.

Next, focus on the hydraulic pump and control valves. Ensure that they are functioning correctly and not causing any restrictions in fluid flow. Use troubleshooting tools such as pressure gauges to gauge system performance and identify any irregularities. Lastly, refer to the tractor's manual for specific troubleshooting procedures and recommended solutions for common hydraulic issues.

By following this step-by-step guide, you can effectively troubleshoot Kubota tractor hydraulics, identify potential problems, and take the necessary steps to address them. Regular maintenance and inspections are key to ensuring smooth and reliable hydraulic system performance.

Tips for Maintaining Kubota Tractor Hydraulics

Maintaining the hydraulics system of your Kubota tractor is crucial for its performance and longevity. Regular maintenance not only ensures smooth operation but also helps prevent costly repairs down the line. Here are some essential tips to keep your Kubota tractor hydraulics in top condition.

Regular Inspections

Inspect the hydraulic system regularly for leaks, cracks, or worn-out components. Pay close attention to hoses, cylinders, and fittings. Any signs of damage should be addressed promptly to prevent further issues.

Fluid Levels and Quality

Check the hydraulic fluid levels regularly and top up as needed. Use the recommended type of hydraulic fluid and keep an eye on its quality. Contaminated or degraded fluid can cause damage to the system, so it's crucial to replace the fluid as per the manufacturer's guidelines.

Filter Maintenance

The hydraulic system's filters play a vital role in capturing contaminants and preventing them from circulating through the system. Regularly inspect and replace filters to ensure that the hydraulics system remains clean and free from debris.

By following these maintenance tips, you can ensure that your Kubota tractor hydraulics operate at their best, providing reliable performance for your agricultural and landscaping needs. Regular maintenance will help you avoid costly downtime and repairs, allowing you to make the most of your equipment.

Consulting a Professional for Complex Kubota Tractor Hydraulics Problems

When it comes to complex Kubota tractor hydraulics problems, seeking the expertise of a professional is crucial for effective resolution. Tractor hydraulics are intricate systems that require specialized knowledge and experience to diagnose and repair. By consulting a professional, you can ensure that your tractor's hydraulics issues are accurately identified and addressed.

Professional technicians have the training and expertise to handle complex Kubota tractor hydraulics problems with precision. They are familiar with the intricacies of hydraulic systems and can effectively troubleshoot and repair any issues that may arise. Additionally, professionals have access to specialized tools and equipment that are essential for diagnosing and fixing complex hydraulic problems.

Attempting to address complex Kubota tractor hydraulics problems without the necessary expertise can lead to further damage and costly repairs. Professionals have a deep understanding of hydraulic system components and can efficiently pinpoint the root cause of any issues. By trusting a professional with your tractor's hydraulic concerns, you can have confidence in the quality of the work performed and the long-term functionality of your equipment.

In conclusion, when faced with complex Kubota tractor hydraulics problems, consulting a professional is the best course of action. Their knowledge, experience, and access to specialized tools make them the most qualified to diagnose and repair intricate hydraulic issues. By entrusting your tractor to a professional, you can ensure that its hydraulic system is in capable hands.

If you want to know other articles similar to Expert Guide to Kubota Tractor Hydraulics Troubleshooting you can visit the category Automotive Mechanics.